To use gas safely

Our corporate group conducts business while putting priority on a stable supply of gas and safety management as an enterprise related to lifestyle infrastructure.

Building a stable supply system

Stable supply and safety management are the top priorities of the gas business, which is our corporate group’s primary business. In addition to optimal measures for respective processes and the reliability of equipment, Kanto Natural Gas Development Co., Ltd. has an integrated control system. We monitor and control the wells, which are the starting points of production, and the network of gas pipelines 24 hours a day, 365 days a year. We control the production and supply of gas with a unified system, to meet the fluctuating demand which depends on season, time of day, etc. In addition, our pipeline network is constituted by multiple grids, so that even if trouble occurs to a pipeline, we can supply gas from another grid by controlling valves without suspending gas supply.

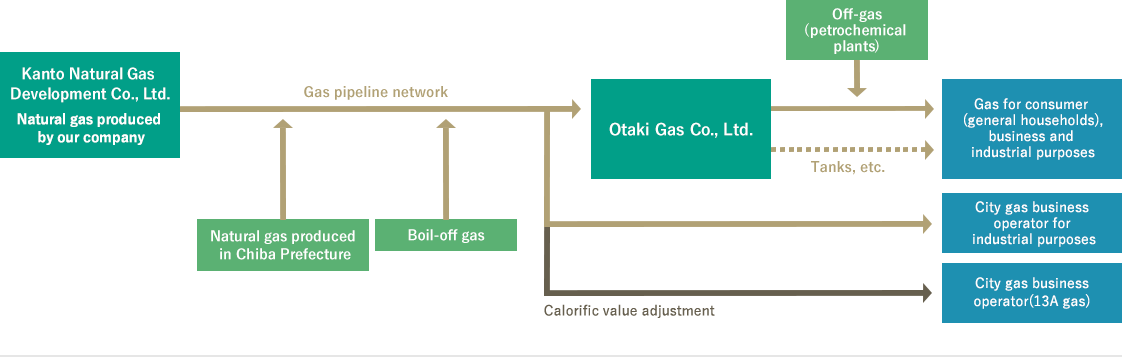

Diverse gas sources

Our corporate group has multiple gas sources to realize a stable gas supply. We have diverse gas supply such as natural gas produced in Chiba Prefecture, LNG (liquefied natural gas), BOG (boil-off gas), which is the LNG that naturally vaporizes in tanks, and off-gas, which is a by-product of manufacturing chemical products at petrochemical plants. By diversifying our gas suppliers, we have built a system that enables a stable supply even during emergencies. We will continue sales promotion based on the best mix of diverse gas sources centered around domestic natural gas, which can be supplied stably for a long period of time, and operate business actively.

Main network of natural gas produced in Chiba Prefecture

LNG network

Establishing a safety system

Otaki Gas has built a system that allows constant monitoring of gas facilities that deliver gas to customers using a remote monitoring system. In addition, in preparation for emergencies such as gas leak, we have a system that allows us to receive reports from customers 24 hours a day, 365 days a year, and dispatch staff quickly to the reported location.

Promoting the distribution of safety equipment

For a safe and comfortable life using gas, we promote the distribtuion of gas appliances and alarms with advanced safety functions, including gas meters equipped with microcomputers that have a gas leakage shutoff function to keep all of you safe.

Inspection of gas equipment

In order to use gas safely, safety inspection is essential. In addition to the regular inspection of gas storage tanks and gas lines buried in the roads, we visit customers’ homes to inspect gas leak and gas appliances and communicate with customers about safety to deepen our trusting relationship.

Anti-seismic measures and disaster prevention

In order to provide a safe and stable supply of gas 24 hours a day, 365 days a year, our corporate group has strengthened and enhanced its facilities, and is preparing adequately for sudden disasters daily and has accumulated the know-how to respond to them.

Measures to reduce damage caused by earthquakes

Gas storage tank

Based on geological surveys, piles are driven into the supporting ground to build a strong reinforced concrete foundation on which pillars and spheres are installed. The spherical part is made of high-strength steel and is designed and constructed to withstand large earthquakes.

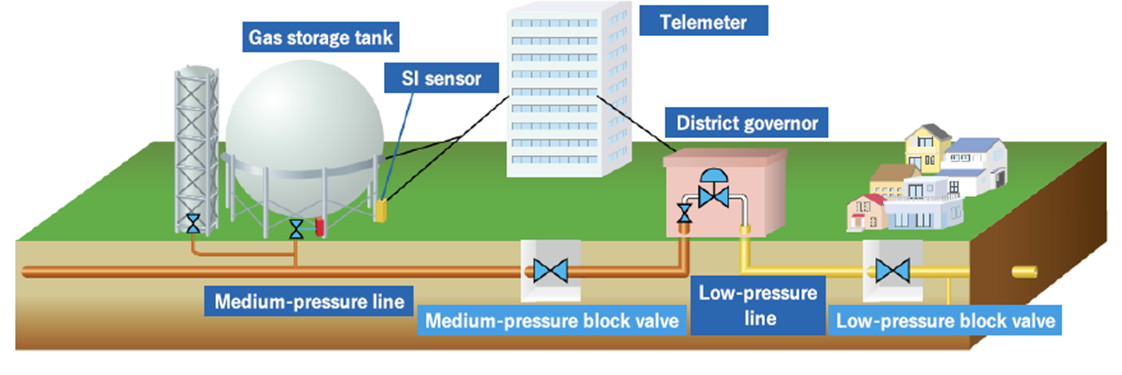

District governor

We are promoting the replacement of governors, which adjust the gas pressure for use in homes, with highly earthquake-resistant equipment. In the event of a large earthquake, the gas supply will be stopped by the governor in conjunction with the seismometer installed in each district governor.

Medium-pressure line

We use welded steel pipes with high strength that can withstand large ground movements for the medium-pressure lines. Even during the Great Hanshin-Awaji Earthquake, gas pipelines constructed using this method suffered almost no damage.

Low-pressure line

Polyethylene pipes with high earthquake resistance are used for making low-pressure lines. Compared to conventional gas lines, polyethylene pipes are more flexible, resistant to earthquakes and differential settlement, and have excellent corrosion resistance.

District governor

District governor Medium-pressure line

Medium-pressure line Low-pressure line

Low-pressure lineEmergency measures against earthquakes

Joint disaster drills with other enterprises

Joint disaster drills with other enterprises

In the case of large-scale disasters that could damage many buildings, gas supply can be suspended in respective blocks (divided areas where gas is supplied) depending on the situation to prevent secondary disasters. About 140 SI sensors installed in each district measure the degree of each earthquake and decide whether or not to suspend the supply. In addition, gas meters equipped with microcomputers installed in each customer’s home can automatically shut off the gas. Furthermore, we have a system that automatically dispatches employees to designated areas even at night and on holidays in the event of an earthquake with a seismic intensity of lower 5 or more within the supply area.

Monitoring system for gas facilities

Telemeters and other devices are used to constantly and remotely monitor gas facilities to swiftly obtain the information from SI sensors installed in each area, as well as pressure and flow rate information from storage tanks and governors. In addition, emergency shutoff valves are installed at key points in the gas lines to stop the gas supply quickly in case of emergencies.

SI sensor

SI sensors measure the numerical value (SI value) that indicates how much a regular building shakes due to an earthquake. The unit used is usually Kine (cm/second). In order to prevent secondary disasters, Otaki Gas has installed approximately 140 SI sensors in each district and will immediately stop the supply if an earthquake exceeding a certain value occurs.

Restoration measures

Restoration support after the Great East Japan Earthquake

Restoration support after the Great East Japan Earthquake

At the time of restoration, efficient restoration work is carried out by dividing blocks where the gas supply was stopped into smaller blocks. In addition, gas in sites that are critical in the event of a disaster, such as hospitals, in areas where the gas supply has been suspended, will be restored with the highest priority, and temporary supplies will be provided by mobile gas generators until the gas supply is resumed. Furthermore, a system has been established for the entire gas industry to provide relief in the event of a large-scale suspension of the gas supply due to a disaster. Our corporate group also dispatched recovery support teams after the Great Hanshin-Awaji Earthquake, the Chuetsu Earthquake, the Chuetsu-oki Earthquake, and the Great East Japan Earthquake.

Business continuity plan in the event of an earthquake

In preparation for disasters, especially earthquakes, our corporate group has formulated a “Disaster Countermeasures Manual” for each group company and is working to improve initial response and recovery capabilities. Kanto Natural Gas Development Co., Ltd. has also developed a business continuity plan in the event of large-scale earthquakes to achieve an operating rate (produced gas volume) of 80% one week after the disaster. Thus, we will not only be able to continue our business in the event of a disaster, but also contribute to the restoration and reconstruction of the region by responding quickly and taking constant measures to reduce damage after determining the priority order for operations in an emergency.